|

Far infrared type for home useCoffee Bean Roaster

『My Stirrer』

|

It will be much

easier if you stir the beans electrically instead of manually. I also came up

with an ingenious plan for a stirrer.

There

are three features.

| ● |

Blade structure. |

| ● |

The stirrer structure

|

| ● |

Connection of the rotating shaft from the motor and the rotating

shaft of the stirring blade. |

|

Let's start with the advantages of using hinges.

|

(Tap the picture to enlarge.) |

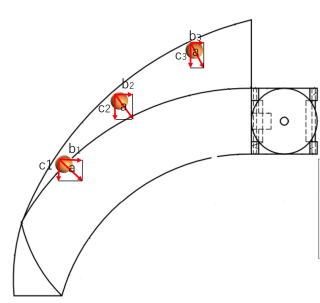

The figure above shows the position of the hinge.

There is a bottom plate positioned at right angles to the rotation axis

that transmits the rotational force of the motor, and the blades are connected

to the two opposite sides of the plate via hinges.

The figure below shows the structure of the hinge. The hinge consists of ”a” and “b” and a “thin rod” which is a red line at the bottom. |

(Tap the picture to enlarge.) |

|

The point is that the blades connected to the bottom plate via the hinges rotate around a thin rod and can rotate horizontally or vertically. When you lift the stirrer by holding it above the axis of rotation and let go of the blades, the blades hang down under their weight at hinges.

The mouth of the parching pan is narrower than bottom, so you can't pass through it with the blades spread horizontally. If the blades are hanging down, you can easily lower the blades to the bottom of the parching pan through a narrow mouth. When the tip of the blade reaches the bottom of the pan, the two blades start sliding in opposite directions and spread out becomes a straight line parallel to the bottom because the blade's tip is curved like a ski plate. And eventually, the entire blade becomes a straight line parallel to the bottom. If you put the beans in the container after this state, the beans will not enter between the blades and the wall of the container.

Af ter roasting, the beans need to be cooled as soon as possible. This is because the beans will be roasted further due to the residual heat while you are in flurried

After the roasting is finished, lift the stirring shaft, then blades will fold vertically in the same way as when you lowered them, so the beans on the blades will spill down. By simply pulling up the stirrer in this way, the stirrer can be removed from the pan without the beans spilling out of the container.

A master roaster once said that "If the roasting end time is different

even by 1 second, it will not be the ideal roasting." Consequently,

it is important that the beans can be transferred to the cooler immediately

after roasting."

In addition, the hinge part “a” is half-opened so the blades can be removed. Therefore, the blades can be removed from the bottom plate to save space when not in use.

|

| ●New Blade design |

Until now, I used a bamboo spatula and moved it in a circular motion to stir the beans.

If you look closely at the movement of the beans when mixing them with

a bamboo spatula, the beans shift sideways. If you rotate the bamboo spatula,

the beans will move in a circular motion.

There seems to be almost no movement between the beans at the top and the

beans near the container's bottom. It appears that the replacement of beans

between the circumference and the center is also small unless it is intentionally

rotated.

Even if a motor rotates the blades, it is the same as a bamboo spatula, and the beans in the center tend to gather near the wall surface due to centrifugal force if the blades are just plate-shaped.

The shape of the blades this time tried to eliminate this drawback.

Please see the next picture. I made blades with clay in order to show how it looks like.

|

|

| In the above photo, the left side screen (Fig. 137) is curved along the

side of the container (parching pan) in both the vertical and depth directions.

For this reason, all beans near the container wall are scooped up with

a scooping board preventing them from slipping into the gap between the

counter plate and the container wall. |

|

| As shown in the photo below, the 135 scooping board and the 136 Screen

board are at right angles at the left end, but the angle increases as you

go to the right, and the screen board leans backward at an angle of 160

degrees. This is the point. |

|

The photo above is a view of the screen board from the back. The height

of the screen plate is getting lower as it is closer to the pivot of the

rotation axis because the screen plate is leaning. The lower the height

of the screen board, the easier it is for the beans to get over the screen

board and fall away. In this way, the beans which were on the top fall

down to the bottom.

。

|

(Tap the picture to enlarge.) |

The beans scooped on the scooping board are pushed by the scooped beans

later and eventually hit the screen board. When the beans hit the screen

board, the repulsive force from the screen board applies force (a) perpendicular

to the screen board surface. No matter where the beans are located, (a)

is the same amount of force. However, since the screen board is curved,

the direction of (a) differs depending on the position of the beans.

When the force of (a) is decomposed, it becomes (b) and (c), but (c) is pushed back by the beans that come later, so that only the force in the direction of (b) remains.

The force (b) moves the beans toward the center by sliding them on the

curved surface of the screen board.

Moreover, depending on the position of the beans, the force of (b) is different,

as (b1)> (b2)> (b3). In other words, the closer the beans are to

the wall surface, the greater the force toward the center. Due to these

forces, the beans move toward the center, but the height of the screen

board becomes lower toward the center, making it easier for the beans to

fall back. On the contrary, the force of (b) becomes weaker toward the

center. Due to these factors, beans are unlikely to accumulate near the

walls or the center, and the beans will be evenly dispersed.

In the above, we only looked at the horizontal force, but in addition to this movement, the beans that got over the screen board plate will change their position from top to bottom

The proposed stirring blades work on the beans, which is not found in bamboo

spatulas and plate-shaped rotating blades, enabling efficient stirring.

The beans scooped on the scooping board are pushed by the scooped beans,

which came later and eventually hit the screen board. When the beans hit

the screen board, the repulsive force from the screen board exerts the

force (a) in the direction perpendicular to the screen board surface to

the beans. When the force of (a) is decomposed, it becomes (b) and (c),

but (c) is pushed back by the beans that come later, as a result, the beans

are eventually turned by the force (b) toward the axis of stirrer along

the screen board. In this way, the beans that accumulate near the wall

by centrifugal force are returned to the center.

As mentioned earlier, the height of the screen board decreases as it goes to right, so the beans eventually get over the screen board and drop to the back of the screen board.

In this way, the beans move from top to bottom. This movement on beans was not found with bamboo spatulas and plate-shaped rotating works.

|

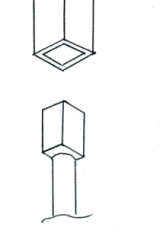

| The rotating shaft descending from the motor in the drive box and the rotating

shaft of the stirring blade are in a male-female relationship as shown

in the figure on the right. point. |

|

Therefore, when the box is moved up and down, as long as the male shaft enters the female hole, the connection is completed without tightening with screws, the height of the stirring blade does not need to be adjusted, and the rotational force of the motor is reliably transmitted to the blade. |

With this structure, the drive box and stirrer can be quickly removed just

after roasting, and the beans can be taken out for being cooled. How quickly

the beans can be cooled after the roasting is an important

|

|

|

|

フラン

スの政治タレーラン スの政治

タレーラン |